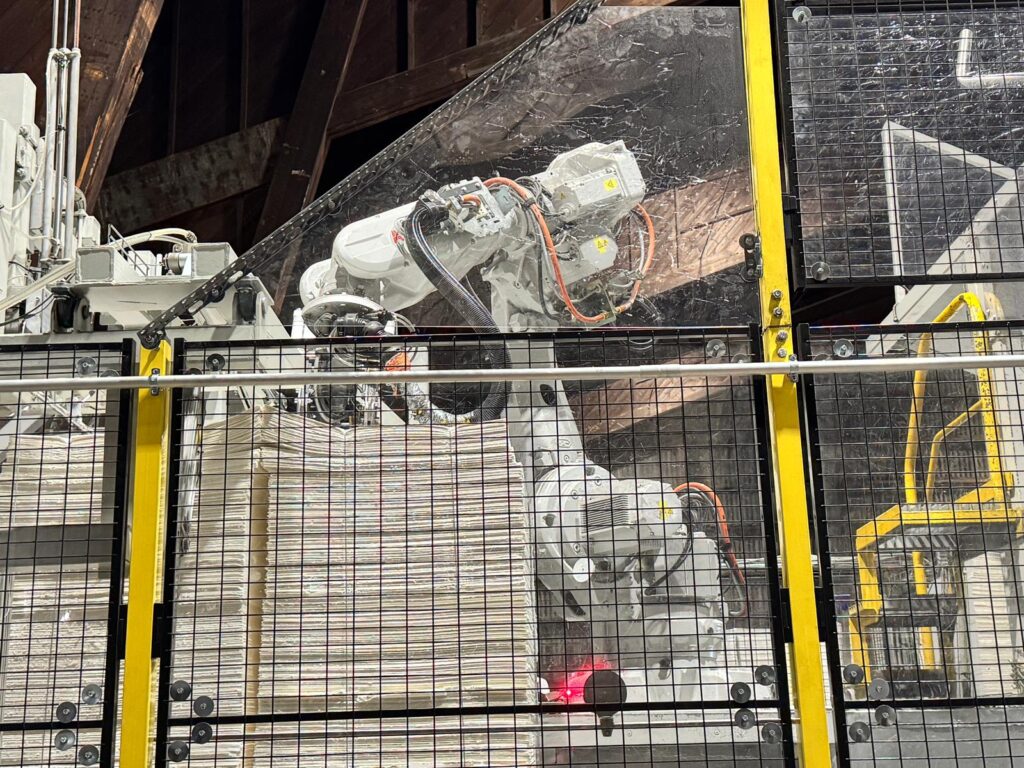

At Euroports, we are committed to continuously improving operational efficiency, enhancing workplace safety, and delivering better service to our customers. A great example of this is the recent implementation of a new automated lifting and wire removal station at our Rauma terminal, which has significantly streamlined the handling of imported pulp.

The robot removes lifting wires from pulp bales and rolls them into bundles for metal recycling. It also inspects the integrity of the strapping wires using a dedicated program and rotates the pulp units into a horizontal position for further processing. The entire process is overseen by an operator who ensures smooth and safe operation.

“Previously, this task was performed manually by stevedores. The new robotic cell significantly improves safety, as pulp handling can now be done 100% automatically within the cell,” says Petri Viinikkala, Technical Manager at Euroports.

By handling lifting and strapping wires already at the port, the process becomes faster and easier for our customers at the paper mills. The automation also reduces the risk of injuries associated with manual wire cutting and handling, further improving occupational safety for our stevedores.

With intact pulp units, the system can process up to 60 units per hour, requiring only a device operator and a machine driver to move the bales to the line and into storage.

"The project was carried out in close cooperation with UPM, based on their operational needs. The equipment was delivered by Notra Oy. The design process was particularly challenging due to the lack of existing references for similar wire removal and inspection stations. You could say this device is one of a kind in the world,” Viinikkala says.

This innovation enables Euroports to carry out modification and repair work on pulp units from all pulp mills safely, efficiently, and cost-effectively.